How RefDestruct Safely Destroys Refrigerants in Compliance with the Montreal Protocol

- James Heckler

- Feb 18, 2025

- 2 min read

Updated: Feb 20, 2025

The Problem with End-of-Life Refrigerants

Refrigerants play a crucial role in commercial cooling systems, but when they reach the end of their useful life, they pose a significant environmental risk. If improperly disposed of, refrigerants can leak into the atmosphere, contributing to global warming and ozone depletion. To prevent this, RefDestruct follows best-practice destruction methods as outlined in the Montreal Protocol, ensuring that these potent greenhouse gases are permanently removed from circulation.

Why Refrigerant Destruction Matters

According to the Montreal Protocol on Substances that Deplete the Ozone Layer, refrigerants like CFCs, HCFCs, and HFCs must be either recycled, reclaimed, or permanently destroyed to prevent environmental harm. While recycling and reclamation are viable options for certain refrigerants, others—especially older, highly potent refrigerants—must be destroyed to eliminate their environmental impact.

How RefDestruct Destroys Refrigerants

RefDestruct utilises approved destruction technologies recognised by the United Nations Environment Programme (UNEP). These methods ensure the complete breakdown of refrigerants into non-harmful components. The following are the primary destruction technologies we use:

1. High-Temperature Incineration (HTI)

Process

Refrigerants are burned at extremely high temperatures (above 1,200°C) in a controlled environment, breaking them down into benign byproducts like carbon dioxide, water vapor, and hydrofluoric acid.

Environmental Safeguards Advanced filtration and scrubbers prevent the release of harmful byproducts.

Effectiveness Over 99.99% destruction efficiency, ensuring complete elimination of refrigerants.

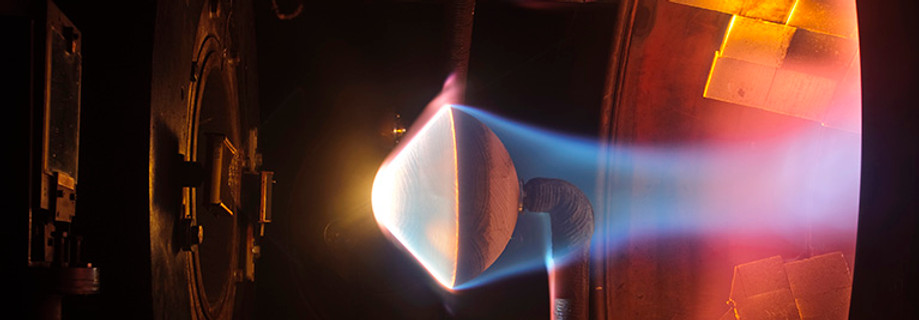

2. Plasma Arc Destruction

Process: Uses a plasma torch that reaches temperatures above 10,000°C to convert refrigerants into elemental gases, which are then neutralised.

Environmental Benefits: No harmful byproducts or emissions.

Effectiveness: Nearly 100% efficiency, making it one of the cleanest destruction methods available.

3. Chemical Neutralisation

Process: Refrigerants are reacted with specific chemicals to break them down into stable, non-toxic compounds.

Application: Often used for small-scale refrigerant destruction where incineration is not feasible. Effectiveness: Over 99% efficiency, ensuring safe breakdown without emissions.

The RefDestruct Commitment to Sustainability

Full Compliance with the Montreal Protocol – All destruction processes meet or exceed international environmental safety standards.

Certified Destruction Reporting – We provide businesses with detailed documentation to support compliance with carbon reporting and sustainability goals.

Circular Economy Contribution – Where possible, byproducts from refrigerant destruction are repurposed in industrial applications, minimising waste.

Why Businesses Should Act Now

With increasing pressure to reduce Scope 1 emissions and meet sustainability targets, refrigerant destruction is a key climate action that businesses must prioritise. The NZ Emissions Trading Scheme (ETS) is evolving, and regulatory bodies are tightening restrictions on refrigerant handling and disposal. Choosing RefDestruct for responsible refrigerant destruction helps your business:

Avoid regulatory penalties for improper disposal.

Reduce corporate carbon footprints in line with net-zero commitments.

Demonstrate ESG leadership in their industry.

Secure carbon credits by properly managing refrigerant disposal.

Partner with RefDestruct Today

RefDestruct is New Zealand’s leader in refrigerant destruction, helping businesses transition away from high-GWP refrigerants safely and sustainably. Contact us today to learn how we can assist in meeting your sustainability targets while ensuring full compliance with the Montreal Protocol

Comments